Warehouse automation is the process of using technology to manage and control the movement of goods in a warehouse. Automation can include the use of robots, conveyor belts, barcode scanners, computers, and other technologies.

What is warehouse automation and what are the benefits of using it in a business setting?

These days, it seems like everything is getting automated. We have self-driving cars, automatic vacuum cleaners, and even robots that can build things. So it shouldn’t be surprising that warehouses are the latest target for automation. Warehouse automation generally refers to the use of technology to perform tasks that would traditionally be done by human workers. This can include anything from loading and unloading heavy boxes to organizing and sorting inventory. There are a number of benefits to automating warehouse tasks.

First of all, it can help to improve worker safety by reducing the need for employees to lift heavy objects or work in dangerous conditions. Additionally, it can increase productivity and efficiency by reducing downtime and increasing accuracy. Finally, it can help to reduce costs by reducing labour expenses. Overall, automation can offer a range of benefits for businesses that operate warehouses.

How does warehouse automation work and what types of equipment are used in this type of system?

When it comes to warehouse automation, there are a few different types of equipment that can be used in order to make the process more efficient. For example, conveyor belts are often used in order to move items from one point to another within the warehouse. Additionally, automated storage and retrieval systems (AS/RS) can be used in order to store items in a specific location and then retrieve them when needed.

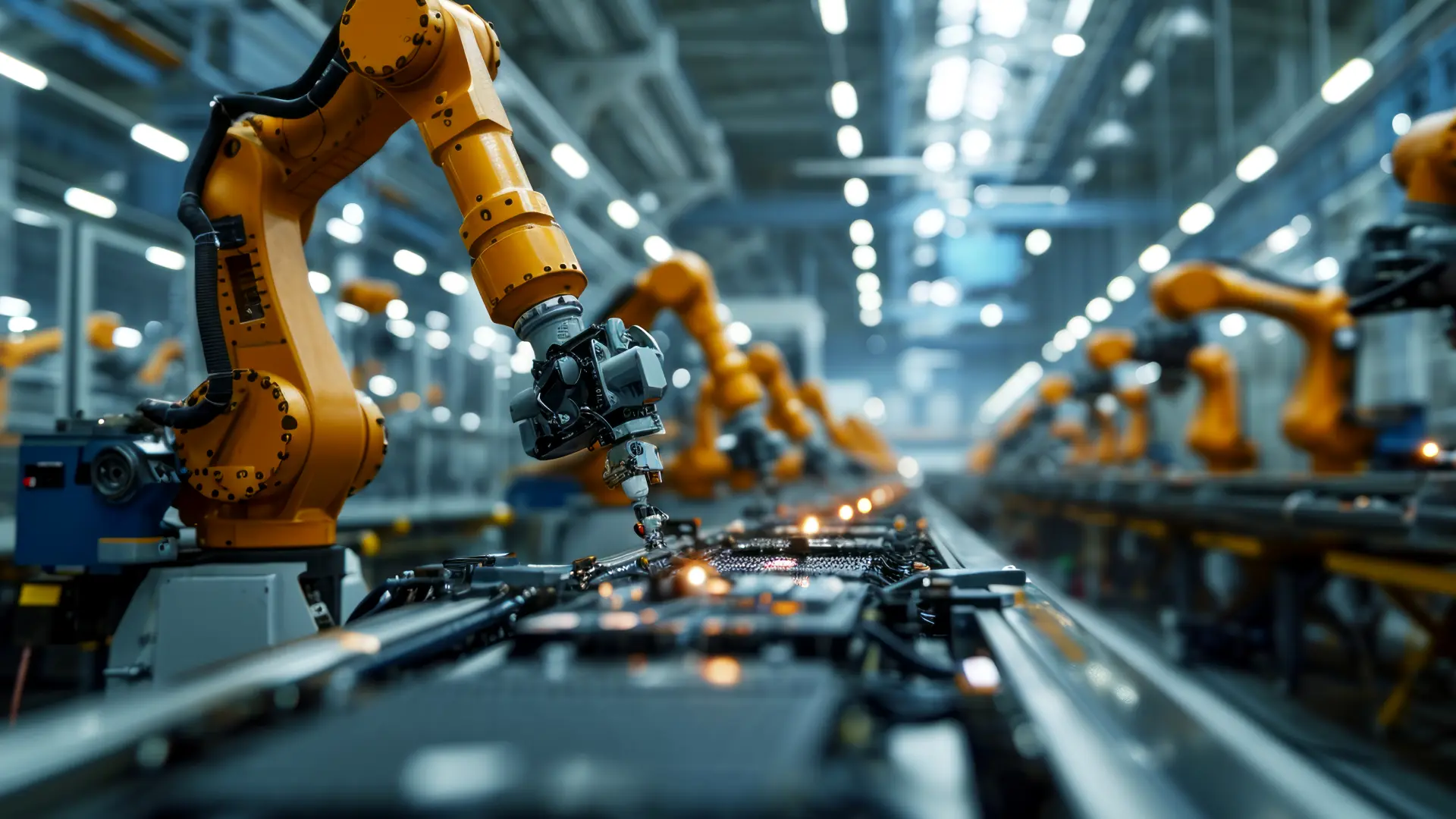

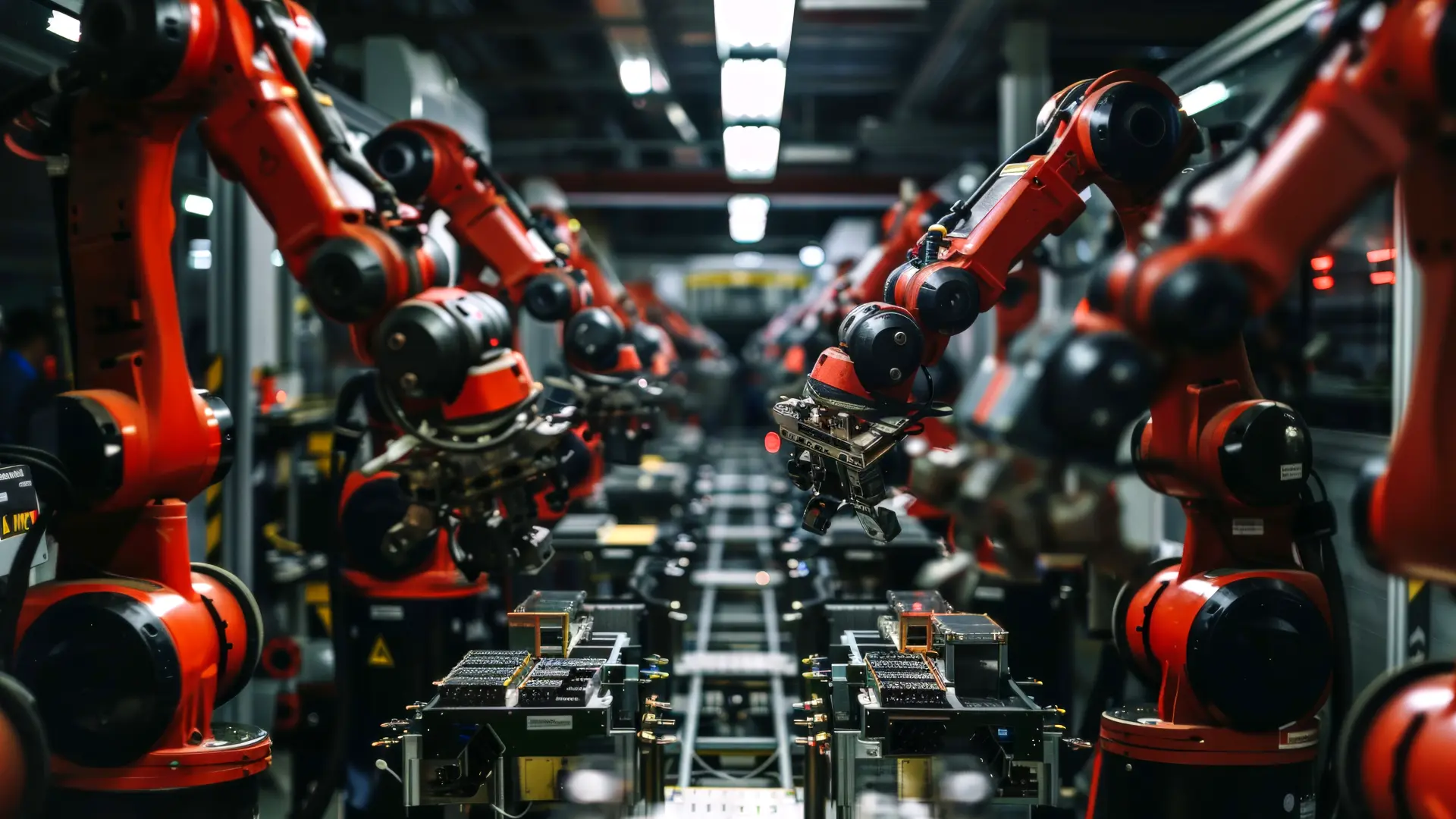

These systems use a variety of sensors and algorithms in order to keep track of inventory levels and ensure that items are being stored properly. Finally, automated guided vehicles (AGVs) can be used in order to move items around the warehouse quickly and efficiently. These vehicles use sensors and artificial intelligence in order to navigate their way through the warehouse without needing human assistance. There is also the use of robotic arms and attachments to aid with automation in warehouses. Overall, warehouse automation can greatly improve the efficiency of any business that relies on it.

What challenges must businesses overcome when implementing a warehouse automation system, and how can they do so successfully?

When it comes to warehouse automation, businesses must overcome a number of challenges to ensure a successful implementation. First and foremost, they need to have a clear understanding of their needs and objectives. Without this, it will be difficult to select the right system and provider. Additionally, businesses need to be aware of the potential risks involved in automating their warehouse.

These include the risk of job loss and the possibility of disruptions to the supply chain. Finally, businesses need to have a plan in place for how they will implement and manage the new system. With careful planning and execution, businesses can overcome these challenges and successfully automate their warehouse.

How has warehouse automation changed the way businesses operate, and what trends can we expect to see in this area in the future?

Businesses have always been searching for ways to operate more efficiently and save money. In recent years, advanced technologies have revolutionized the way warehouses are operated. Automated systems are now used to track inventory levels, determine the most efficient routes for picking and packing orders, and even load and unload vehicles.

As a result, businesses have been able to drastically reduce their operating costs while also increasing their accuracy and efficiency. Looking to the future, it is clear that warehouse automation will continue to evolve and play an increasingly important role in the way businesses operate. New technologies, such as robots and artificial intelligence, hold the potential to further increase efficiency and reduce costs. As businesses strive to stay ahead of the competition, we can expect to see continued innovation in this area in the years to come.

Conclusion

In conclusion, warehouse automation is a growing trend in the business world that offers many benefits, including increased efficiency and accuracy, reduced labor costs, and improved safety. Though there are some challenges to implementing such a system, these can be overcome with careful planning and execution. As we move into the future, it is expected that more and more businesses will adopt warehouse automation systems in order to stay competitive.