Soft robotics is an emerging field within the broader domain of robotics that focuses on creating robots from highly flexible materials. Unlike traditional robots, which are typically constructed from rigid components such as metal and plastic, soft robots are built using materials like silicone, rubber, and other elastic substances. This flexibility allows soft robots to mimic the movements and adaptability of living organisms more closely. In the context of warehouse robotics and robot arms, soft robotics offers promising advancements that could revolutionise the industry.

The Fundamentals of Soft Robotics

Soft robotics diverges from conventional robotics by utilising compliant materials that can stretch, bend, and twist. This characteristic enables soft robots to perform delicate tasks that would be challenging for their rigid counterparts. The design of soft robots often draws inspiration from biological systems, such as octopuses, worms, and human muscles, to achieve high levels of dexterity and adaptability.

One of the key components of soft robotics is the use of soft actuators. These actuators are responsible for the movement and control of the robot. Unlike traditional actuators that rely on motors and gears, soft actuators employ methods such as pneumatics (air pressure), hydraulics (fluid pressure), and shape-memory alloys (materials that change shape in response to temperature). This allows soft robots to perform complex movements with a gentler touch, making them ideal for handling fragile objects.

Applications in Warehouse Robotics

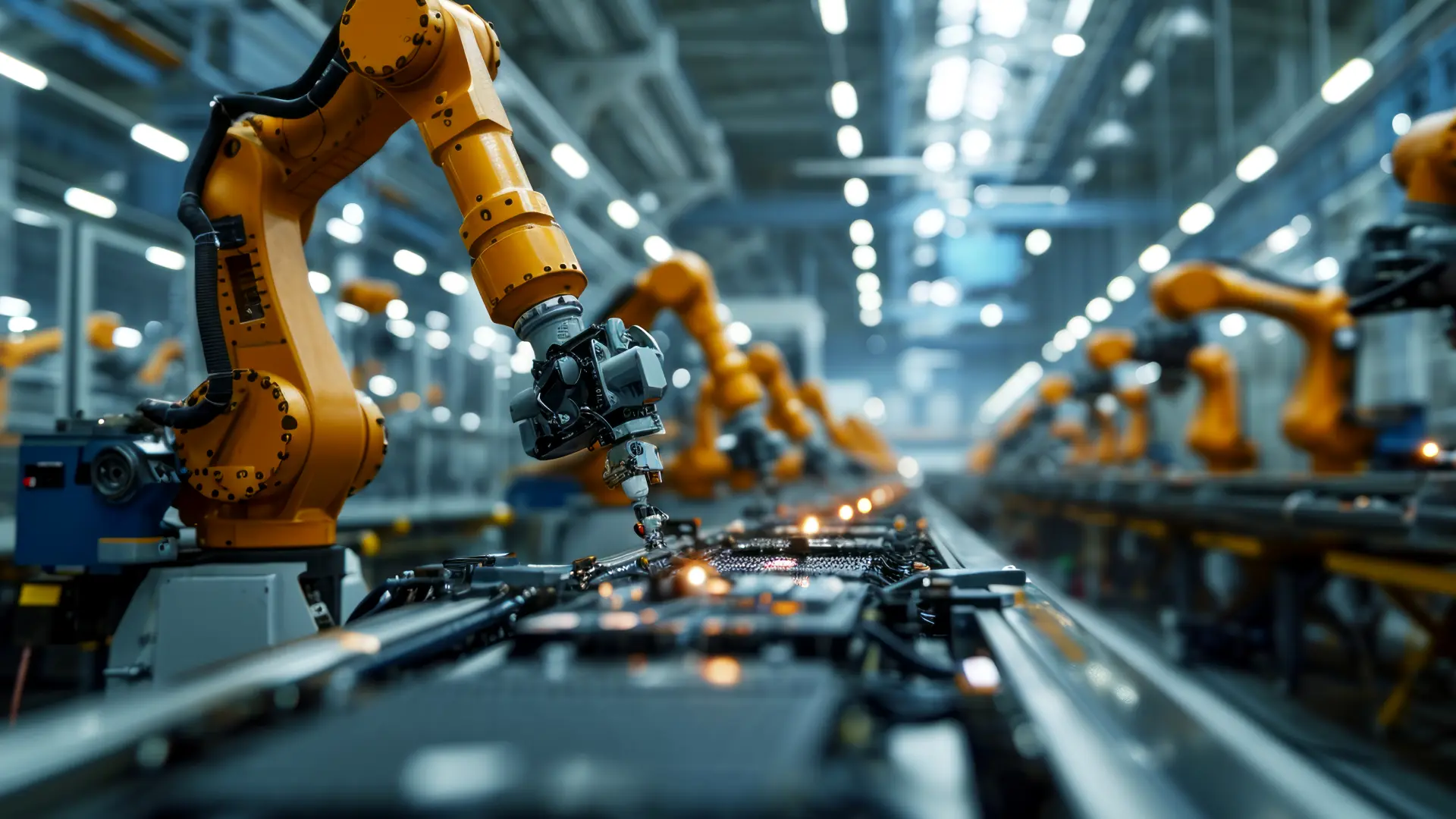

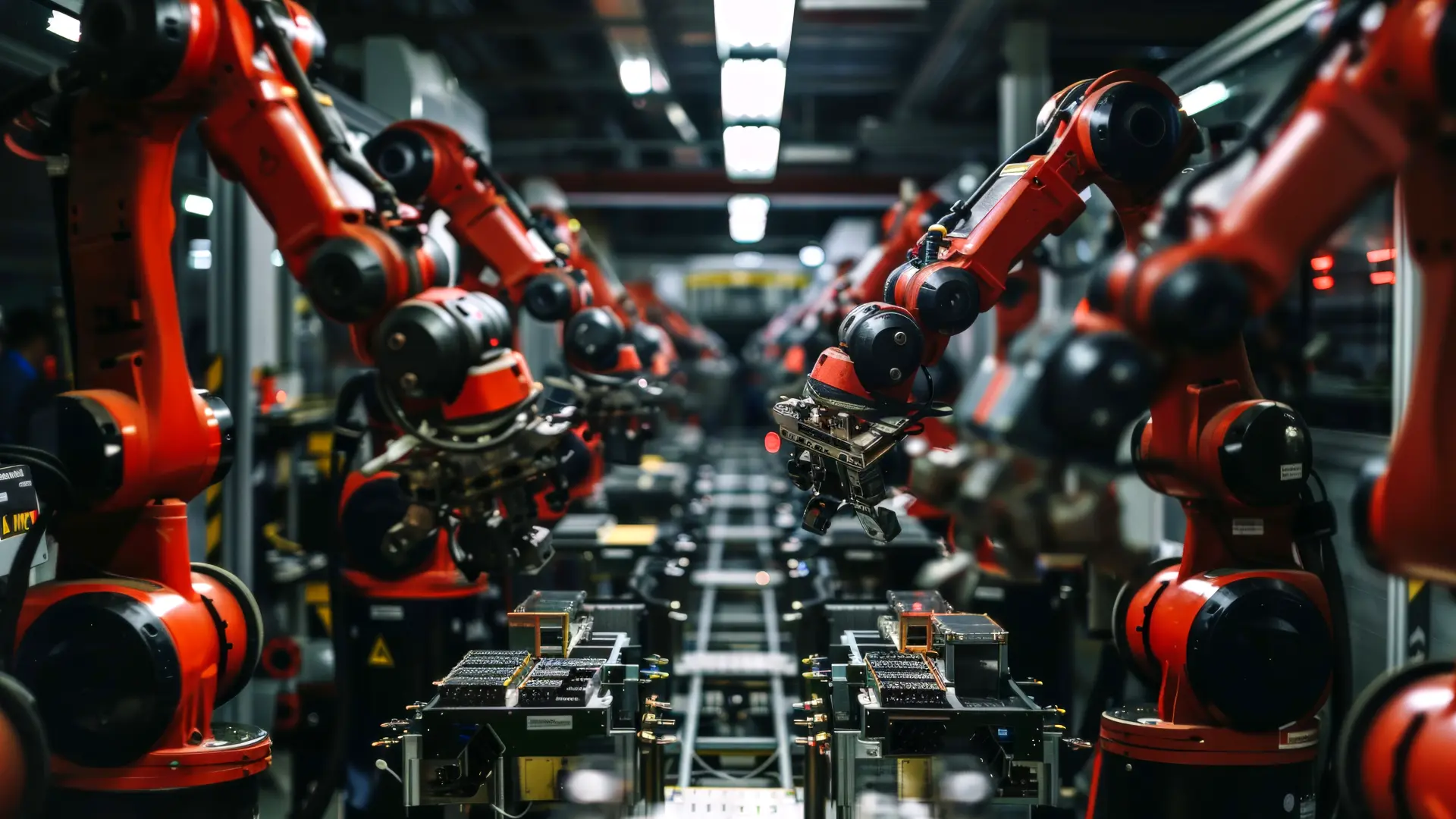

The logistics and warehousing sector stands to benefit significantly from the integration of soft robotics. Traditional warehouse robotics are efficient at performing repetitive tasks such as sorting, packing, and transporting goods. However, their rigid structures can limit their ability to handle delicate items or navigate complex environments. Soft robotics addresses these limitations by offering enhanced flexibility and precision.

Gentle Handling of Fragile Items

Soft robotic grippers can handle fragile items, such as glassware, electronics, and produce, with greater care than conventional robotic arms. Their ability to conform to the shape of the objects they pick up reduces the risk of damage. This is particularly useful in industries where the integrity of the product is paramount.

Adaptability to Variable Tasks

Soft robots can easily adapt to a variety of tasks within a warehouse setting. Their flexible nature allows them to switch between different types of objects and tasks without requiring extensive reconfiguration. This adaptability enhances the efficiency of warehouse operations, as the same soft robot can be used for multiple functions, from picking and packing to sorting and organising.

Safety in Human-Robot Interaction

Safety is a critical concern in environments where humans and robots work alongside each other. The soft, compliant nature of soft robots makes them inherently safer than rigid robots. In the event of a collision, a soft robot is less likely to cause injury to human workers. This characteristic promotes a safer working environment and facilitates closer collaboration between humans and robots.

Advances in Soft Robotics Technology

The field of soft robotics is continuously evolving, with ongoing research and development leading to new innovations. Advances in materials science, manufacturing techniques, and control systems are driving the progress of soft robotics.

Material Innovations

Researchers are exploring new materials that enhance the performance of soft robots. These include self-healing materials that can repair themselves after damage and biodegradable materials that reduce environmental impact. Additionally, smart materials that respond to stimuli such as light, heat, or magnetic fields are being developed to create more responsive and adaptable soft robots.

Manufacturing Techniques

Innovations in manufacturing techniques, such as 3D printing and soft lithography, are enabling the production of more complex and intricate soft robotic structures. These techniques allow for the precise fabrication of soft actuators and sensors, improving the functionality and reliability of soft robots.

Advanced Control Systems

Control systems for soft robots are also advancing, with the development of sophisticated algorithms and machine learning techniques. These systems enable soft robots to perform complex tasks autonomously and adapt to changing environments in real-time. The integration of sensors and artificial intelligence enhances the capability of soft robots to perceive and interact with their surroundings.

Future Prospects and Challenges

While the potential of soft robotics is immense, there are still challenges to overcome before widespread adoption in warehouse environments can be realised. One of the primary challenges is the durability of soft materials. Although soft robots are designed to be flexible, they must also be robust enough to withstand the rigours of industrial applications. Research is ongoing to develop materials that offer a balance between flexibility and durability.

Another challenge is the complexity of control systems. Unlike rigid robots, which have well-defined mechanical structures, the flexible nature of soft robots makes their movement more difficult to predict and control. Advanced algorithms and machine learning are helping to address this challenge, but there is still much work to be done.

Despite these challenges, the future of soft robotics in warehouse settings looks promising. As technology continues to advance, soft robots are likely to become an integral part of the logistics and warehousing industry. Their ability to handle delicate items, adapt to various tasks, and ensure safety in human-robot interactions positions them as a key innovation in the future of robotics.

In conclusion, soft robotics represents a significant leap forward in the field of robotics, particularly within warehouse environments. By leveraging the flexibility and adaptability of soft materials, these robots offer solutions to some of the limitations of traditional rigid robots. As research and development continue to push the boundaries of what is possible, soft robotics is set to play a transformative role in the future of automation and robotics.