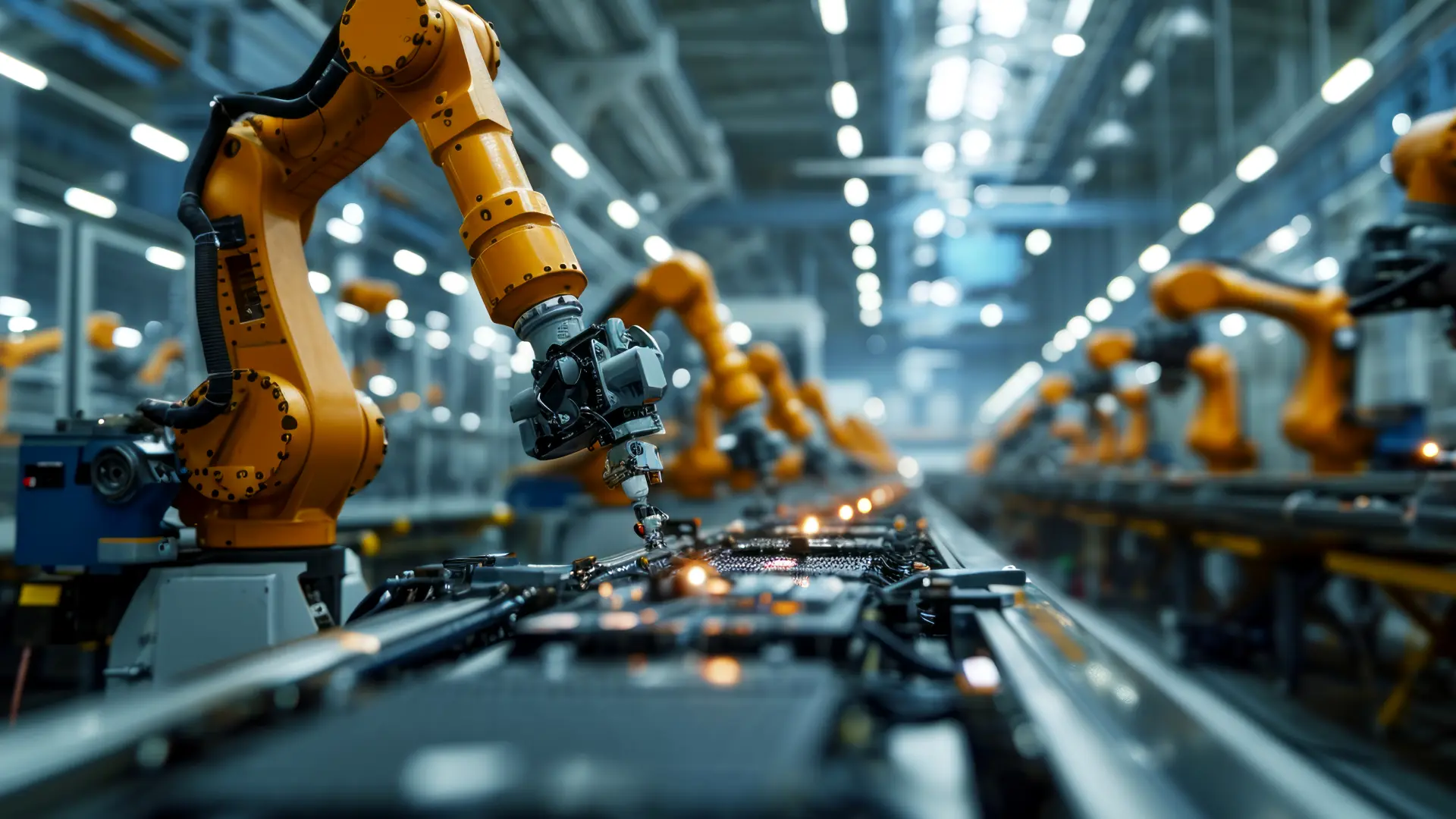

In this article, we take a look at some of the different ways that robotic arms can be used in warehouses and factories.

Robotic arms are becoming more and more common in warehouses and factories, as they offer a number of advantages over traditional methods of manufacturing and handling products.

What are robotic arms and what do they do

In factories and warehouses, robotic arms are often used for tasks that are dangerous, tedious or time-consuming for humans. For example, robotic arms can be used to pick and pack products, load and unload products, and transport products. Robotic arms can also be used to inspect products, label products, and sort products.

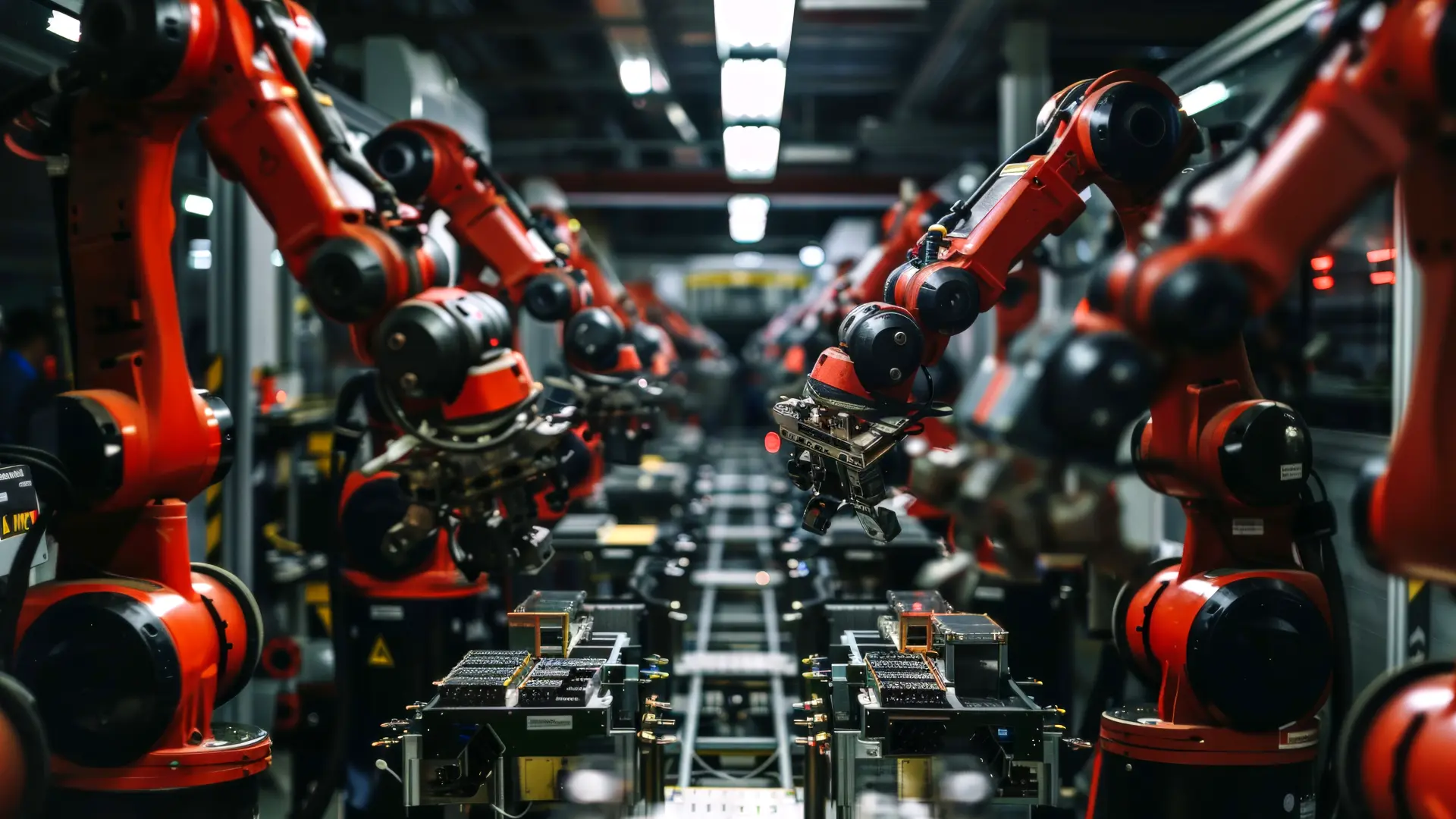

How are robotic arms used in warehouses and factories?

There is a range of different robot arms and attachment combinations that can be used in warehouses and factories, and allow for a range of different tasks to be automated. For example, handling products can be automated using a gripper attachment, while inspection can be carried out using a camera attachment. Additionally, many warehouses use robot arms to pick and pack products as well as to load and unload them from trailers and containers.

Other uses for robot arms in warehouses could be to sort or arrange products on shelves or conveyors, or to label products with barcodes or other markings.

- Handling Products

- Picking and Packing Products

- Loading and Unloading Products

- Inspecting Products

- Labelling Products

- Transporting Products

- Sorting Products

What are the different types of robotic arms?

The two main types of robotic arms are:

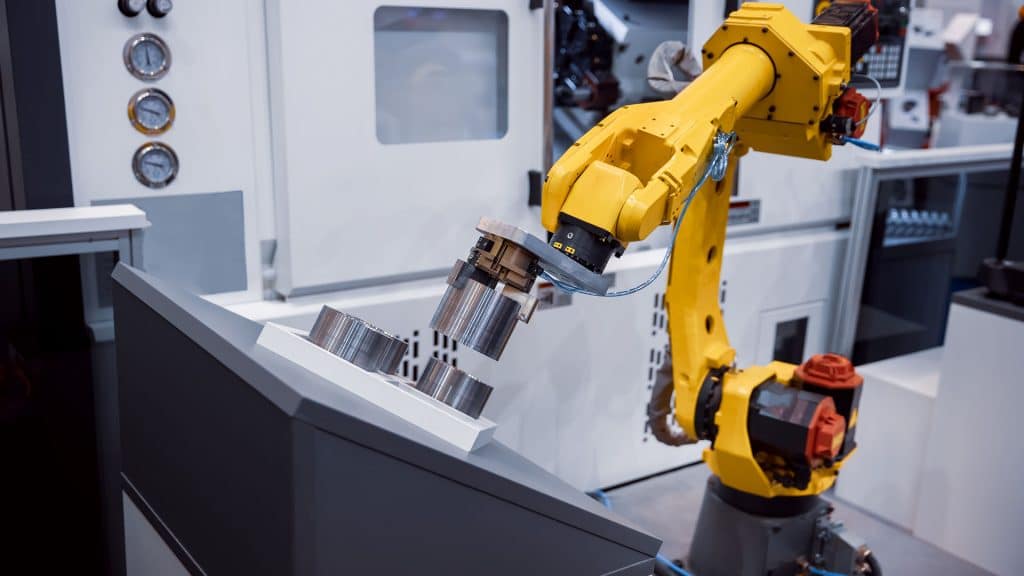

Articulated Robotic Arms

These robotic arms have a number of joints that allow them to move in different directions.

Cartesian Robotic Arms

These robotic arms move along three linear axes (X, Y and Z) and are very flexible.

Both of these robotic arm types can be used in a warehouse or factory environment.

Both of these robotic arm types are commonly used in warehouses and factory environments and offer different advantages. For example, articulated robotic arms are often used for tasks that require more dexterity and flexibility, while cartesian robotic arms are typically used for tasks that require more precision.

The advantages of using robotic arms in warehouses and factories

Robotic arms offer a number of benefits over traditional methods of manufacturing and handling products. Some of the benefits of using robotic arms include:

Increased Productivity

Robotic arms can work faster than humans, which means that more products can be manufactured or handled in a shorter period of time.

Reduced Error Rates

Robotic arms can reduce the number of errors that are made during the manufacturing or handling process.

Increased Safety

Robotic arms can be used for tasks that are dangerous for humans, such as handling hazardous materials.

Reduced Costs

In some cases, using robotic arms can help to reduce the overall cost of the manufacturing or handling process.

What are the challenges of using robotic arms?

While there are many benefits to using robotic arms, there are also some challenges that need to be considered. Some of the challenges of using robotic arms include:

Programming

Robotic arms need to be programmed before they can be used. This can be a challenge, as programming robotic arms can be complex and time-consuming.

Set-Up

Robotic arms need to be set up before they can be used. This can be a challenge, as setting up robotic arms can be complex and time-consuming.

Maintenance

Robotic arms need to be maintained on a regular basis. This can be a challenge, as maintaining robotic arms can be complex and time-consuming.

Cost

Robotic arms can be expensive to purchase and maintain.

Despite the challenges, there are many benefits to using robotic arms in warehouses and factories. Robotic arms can help to increase productivity, reduce error rates, and increase safety. In some cases, using robotic arms can also help to reduce the overall cost of the manufacturing or handling process.

Contact Robotic Products

If you are looking for a range of robot arms and attachments to suit your warehouse or factory, contact Robotic Products for a consultation. We have a wide range of products to suit different needs and budgets, and our team can advise you on the best solution for your business.