The UK has been a major player in the global economy for years, producing everything from car parts to pharmaceuticals. But the industry has been under pressure lately, with global competition, rising costs and higher quality standards.

Against this backdrop, robotics has emerged as the game changer, giving UK manufacturers the chance to be more productive, more precise and competitive.

We, at Robotic Products have made this blog that looks at how robotics impacts the UK manufacturing sector.

We’ll explore everything from efficiency to the workforce and how robotics is not only changing how products are made but also opening up a more sustainable, cost-effective and resilient manufacturing future for Britain.

The Rise of Robotics in UK Manufacturing

Robotics in manufacturing isn’t new, its roots go back to the early days of industrial automation in the mid-20th century. But recent technology advancements have taken robotics to a new level, robots can now do complex tasks at speed and accuracy.

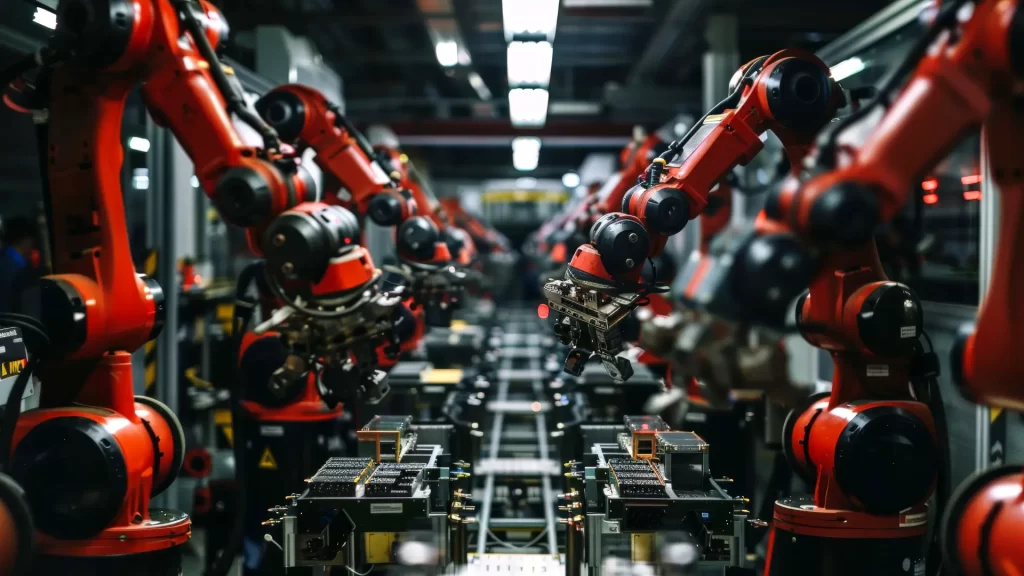

In the UK the adoption of robotics is mainly driven by the need to produce more while keeping quality control tight—a necessity in industries like aerospace, automotive and electronics where precision and consistency are key.

Today the shift to robotics is happening across the UK, driven by government initiatives and businesses realising automation is key to long-term survival in a digital world.

From small and medium enterprises (SMEs) to large corporations, manufacturers are investing in robotics to stay competitive globally. This widespread adoption is a big step towards a future where robotics will be the foundation of UK manufacturing.

More Productivity and Efficiency

One of the biggest benefits of robotics in manufacturing is the significant increase in productivity and efficiency. Robots can do repetitive tasks with precision, reduce human error and free up human workers to do more complex, strategic tasks.

In production lines where speed and precision are key, such as packaging, welding and assembly, robot arms streamline the process, allowing companies to produce more in less time and with more consistency.

Case studies show how robotic systems have transformed UK production floors to achieve efficiency gains that were previously impossible. In high-volume sectors like electronics and consumer goods, robots have reduced cycle times and increased output.

This efficiency helps UK manufacturers meet deadlines, clear backlogs and maintain high standards and reputation in the domestic and international markets.

Quality and Precision

Robotics hasn’t just sped up production but also improved the quality and precision of products. Robots can do tasks with an unmatched level of accuracy, which is critical in industries where even a slight deviation can cause product defects or safety issues.

For example in pharmaceutical and automotive industries the precision of robotics ensures each component or product meets strict quality standards, reducing the risk of recalls or quality issues.

By improving quality control processes robots help UK manufacturers produce products that meet exacting specifications customer satisfaction and brand loyalty.

Automated quality inspection systems can also detect defects that human inspectors may miss, ensuring consistency throughout production. This level of precision meets regulatory standards and builds trust with consumers, making UK made products synonymous with quality.

Workforce Transformation

While the adoption of robotics in manufacturing has raised concerns about job displacement, we need to see this as an opportunity for workforce evolution.

Robots are not here to replace human workers but to work alongside them, do the repetitive and strenuous tasks so human workers can focus on higher level tasks.

This shift creates a demand for new skills, a chance for workers to upskill or reskill in robotics, maintenance and programming which are in high demand in today’s job market.

UK manufacturers are seizing this opportunity to develop a skilled workforce by investing in training programmes that prepare employees for the robot age.

By equipping workers with the skills to manage and operate robotic systems companies will improve productivity and have a more engaged and adaptable workforce.

This proves that human expertise is still crucial in a robotised workplace where people and machines can work together to achieve great things.

Cost and Competitiveness

Robotics gives you two benefits in manufacturing: more output and lower operational costs. While the initial investment in robotic systems can be high, the long-term savings are often substantial.

Robots reduce the need for overtime and minimise the costs of human error such as material waste or product defects. So manufacturers can reduce their overall costs and make British-made products more competitive in the domestic and international markets.

In today’s global economy reducing costs is key for UK manufacturers to compete with lower-cost producers abroad. By using robotics to streamline and reduce costs UK manufacturers can increase their global competitiveness and create a more resilient sector.

This focus on efficiency makes the UK a viable alternative to offshore manufacturing and will grow local industries and the national economy.

Sustainability and Robotics in Manufacturing

The adoption of robotics in manufacturing has also brought new opportunities for sustainability, helping UK businesses reduce their environmental footprint.

Robots can be programmed to use energy more efficiently and reduce electricity consumption and waste in the production process.

Robotic systems also use resources more efficiently so companies can produce with less material and lower emissions – a key consideration in today’s eco-conscious world.

Sustainability is top of the agenda for UK manufacturers, robotics enables greener production practices that benefit both the planet and the bottom line.

By reducing waste and improving energy efficiency manufacturers can reduce costs and appeal to environmentally aware consumers.

This commitment to sustainability will enhance brand reputation and align with government initiatives for green policies, a future where UK manufacturing is both technologically advanced and environmentally responsible.

Challenges and Considerations

Despite the many benefits, the adoption of robotics in manufacturing comes with its own challenges. High initial costs, skills shortages and technological limitations are common barriers that businesses, especially SMEs will face when considering robotics.

There are also regulatory and safety considerations as manufacturers need to ensure robotic systems are safe and don’t compromise worker health.

Overcoming these challenges will require a collaborative approach between industry leaders, government and education institutions. By providing financial incentives, encouraging innovation and training programmes the UK can overcome these barriers and have a manufacturing sector that fully utilises robotics.

This proactive approach will ensure the benefits of robotics are available to all manufacturers, big and small and strengthen the UK’s industrial base.

The Future of Robotics in UK Manufacturing

Looking forward the future of robotics in UK manufacturing is bright. Emerging trends like artificial intelligence integration and collaborative robots will transform production lines even more.

Collaborative robots or “cobots” are designed to work alongside humans, enabling flexible and adaptable manufacturing processes that can change to new products and demand without the need for reprogramming.

As these technologies evolve, robotics will become an essential part of UK manufacturing, enabling the sector to achieve unprecedented levels of productivity, sustainability, and innovation.

By embracing these advancements, UK manufacturers can be market leaders and have a bright and technologically advanced future for the industry.

Conclusion

The impact of robotics on UK manufacturing can’t be ignored. From productivity and precision to a more skilled workforce and lower costs robotics has changed how products are made and set the stage for a competitive and sustainable industry.

As UK manufacturers continue to adopt robotics the sector will go even further, where human ingenuity and robotic precision go hand in hand.

In summary, robotics offers a lot for UK manufacturing, productivity, quality and sustainability in equal measure. By overcoming the current challenges and grasping the opportunities of emerging technologies the UK manufacturing sector will thrive and be a global leader in a fast-changing industrial world.