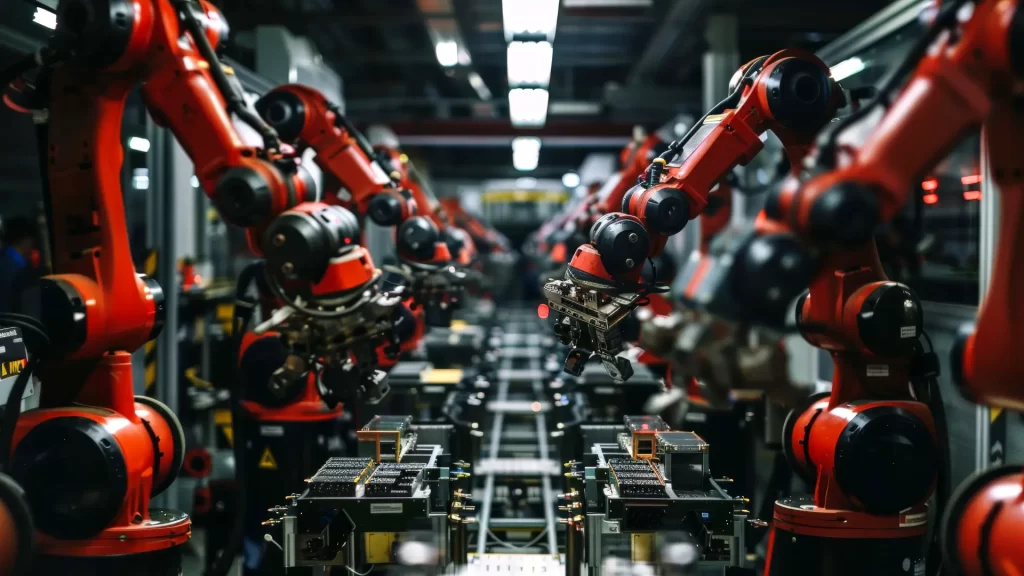

Warehouse automation has evolved significantly over the last few decades, with robotic systems playing a key role in transforming logistics operations. Traditionally, manual labour was required for most tasks, but technological advancements, particularly in robotics, have allowed warehouses to function more efficiently.

Robotic arms are at the forefront of this revolution, improving both speed and accuracy in a range of activities, from sorting packages to assembling orders.

The integration of robotic arms in warehouses allows for quicker, more reliable processing of goods. These robotic systems are designed to work around the clock, without the limitations faced by human workers such as fatigue or injury.

By automating repetitive and physically demanding tasks, these robotic arms free up human workers for more strategic, decision-based roles, helping warehouses run smoother and more productively than ever before.

The Role of Robotic Arms in Streamlining Operations

Robotic arms are pivotal in streamlining various operations within a warehouse. One of the primary functions they perform is picking and packing products for shipment.

By using advanced vision systems and precision control, robotic arms can pick up items from shelves with accuracy, sort them, and pack them into boxes. This process is much faster than manual methods, reducing the time it takes to fulfil orders and lowering the chances of human error.

Another important role robotic arms play is in sorting and shelving. With their ability to lift and move heavy objects, they can place items in storage locations more efficiently than human workers.

Their precision and speed in managing stock not only improve workflow but also help with inventory accuracy. By automating these processes, warehouses can maintain a continuous flow of goods, reducing bottlenecks and ensuring that products are readily available for shipping.

Reducing Costs and Increasing Productivity

One of the major benefits of implementing robotic arms in warehouses is the reduction of operational costs. While the initial investment in robotics technology may be significant, the long-term savings are substantial.

Automation eliminates the need for temporary labour and reduces reliance on human workers for physically demanding tasks. This leads to lower wages and benefits costs, as well as fewer instances of workplace injuries, which can be costly for businesses.

The increase in productivity provided by robotic arms is another crucial factor driving their adoption. With the ability to work 24/7 without rest, robotic arms enable warehouses to achieve a higher output than would be possible with a solely human workforce.

Faster product picking, sorting, and packing reduce the time it takes to process orders, leading to quicker delivery times and improved customer satisfaction. The combination of reduced costs and enhanced productivity gives companies a significant competitive advantage in the fast-paced world of e-commerce.

Improved Safety and Reduced Labour Costs

Safety is a top priority in any warehouse, and robotic arms help to mitigate many of the risks associated with manual labour. Tasks such as lifting heavy boxes or handling hazardous materials can be dangerous for workers, but robotic arms can perform these jobs without the risk of injury.

By reducing the need for workers to handle physical tasks, the likelihood of accidents and the associated costs is greatly diminished, creating a safer working environment for all employees.

Additionally, robotic arms can help reduce labour costs by taking over repetitive and strenuous tasks. With the automation of tasks such as picking and packing, warehouses can operate with fewer employees, reducing the need for temporary labour during peak seasons.

This not only lowers staffing costs but also ensures that employees can focus on higher-value tasks that require critical thinking and decision-making, increasing overall job satisfaction and efficiency.

The Future of Robotic Arms in Warehousing

Looking ahead, the future of robotic arms in warehousing is promising, with new technological advancements on the horizon. As artificial intelligence (AI) and machine learning continue to evolve, robotic systems are becoming smarter, more adaptable, and more intuitive.

This allows them to perform increasingly complex tasks with greater flexibility. For example, AI can enable robotic arms to learn from their environment, adjusting their movements based on new data or changes in the layout of the warehouse.

Moreover, the continued development of collaborative robots (cobots) promises even greater benefits for warehouse automation. These robots are designed to work alongside human employees, enhancing productivity without replacing workers entirely.

As the technology improves, robotic arms will become even more integrated into warehouse operations, helping businesses streamline their processes and meet the growing demands of e-commerce more effectively.

Conclusion

Robotic arms have had a profound impact on warehouse automation, offering numerous benefits including increased efficiency, reduced costs, and enhanced safety.

By automating repetitive tasks, warehouses can operate more smoothly, allowing for faster order fulfilment and reduced errors.

As technological advancements continue, robotic arms will only become more capable, ushering in a new era of warehouse automation that will help businesses stay competitive in the evolving logistics landscape.

The future of warehousing is undoubtedly automated, and robotic arms will be at the heart of this transformation.