In the fast-paced world of automation, efficiency is the key to staying competitive, and at Robotic Products, we are dedicated to offering the most innovative solutions for industrial automation.

One of the key technologies transforming modern robotic operations is the swivel tool changer. These sophisticated systems enable robots to change tools seamlessly without halting the production process, reducing downtime and significantly enhancing operational efficiency.

The ability to quickly swap tools allows businesses to handle complex manufacturing tasks with greater flexibility.

Swivel tool changers, by design, address one of the most persistent challenges in automation: the need for robots to perform multiple functions within a single operation.

Traditionally, robots required manual intervention for tool changes, leading to prolonged downtime and decreased productivity.

By integrating swivel tool changers, businesses can now automate this process entirely, ensuring that robots can switch between tasks autonomously and maintain continuous workflow, ultimately leading to higher throughput and lower operational costs.

What are Swivel Tool Changers?

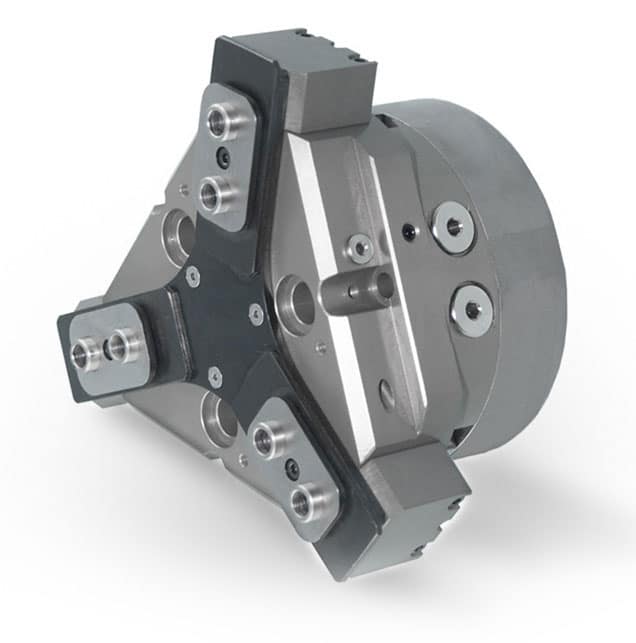

Swivel tool changers are advanced mechanical devices that allow industrial robots to quickly and efficiently change their end effectors, such as grippers or welding tools, without human intervention. They are specifically designed to enable rotation, ensuring that tools can be swapped out at various angles.

This is particularly useful in operations that require a high degree of precision or versatility, such as assembly lines or robotic welding. At Robotic Products, we provide swivel tool changers that are engineered for durability and designed to withstand the rigorous demands of industrial environments.

Industries across the globe, from automotive manufacturing to aerospace, rely on swivel tool changers to maximise their robotic system’s performance.

These changes reduce the need for dedicated robots for specific tasks, making it easier to reconfigure workstations and accommodate a wide range of production requirements.

By incorporating swivel tool changers, companies can significantly boost the adaptability of their robotic fleets, allowing them to tackle a more diverse set of applications without the need for constant reprogramming.

Key Benefits of Swivel Tool Changers

One of the primary advantages of swivel tool changers is the increased flexibility they bring to robotic operations. Robots fitted with these changers can seamlessly transition between different tasks, such as picking and placing, welding, or material handling, all within the same production cycle.

This not only improves the robot’s functionality but also reduces the need for multiple robots, saving space and costs. Additionally, swivel tool changers help maintain high levels of precision, ensuring that every tool is positioned accurately for each task, reducing the margin for error.

Another significant benefit is the reduction in downtime during tool changes. In traditional setups, tool changes can be a time-consuming process, often requiring manual intervention that halts production.

Swivel tool changers automate this process, allowing for rapid, on-the-fly changes without interrupting the flow of operations. This leads to increased productivity, as robots can perform continuous tasks without unnecessary pauses.

At Robotic Products, we understand the importance of keeping your production lines running smoothly, and our swivel tool changers are designed with this goal in mind.

Swivel Tool Changers in Action

Swivel tool changers are revolutionising industries such as automotive manufacturing, where robots are required to perform multiple tasks, including assembly, welding, and part inspection, within a single production line. In these environments, the ability to switch tools quickly is critical to maintaining productivity and meeting the high demand for output.

For instance, a robot working on a car assembly line might need to switch between different types of welding tools or grippers to complete various stages of the production process. With a swivel tool changer, this transition is smooth and efficient, ensuring that no time is wasted.

At Robotic Products, we’ve seen first-hand the benefits that swivel tool changers bring to complex operations. In one case, a manufacturer in the electronics industry was able to reduce their production time by 20% simply by incorporating swivel tool changers into their robotic systems.

These changes allowed their robots to swiftly alternate between delicate tasks, such as soldering and placing components, with minimal downtime. The result was a more efficient, streamlined process that improved their overall production capacity and reduced operational costs.

The Future of Robotic Tool Changers

The future of swivel tool changers is bright, with advancements in technology promising even greater flexibility and efficiency for robotic systems. Innovations such as smart tool changers that can automatically recognise and adapt to the tools they connect with are already on the horizon.

These developments will further reduce the need for manual oversight, allowing robots to autonomously manage a wider range of tasks. At Robotic Products, we are constantly researching and developing new technologies to ensure that our customers stay ahead of the curve.

As automation continues to evolve, the integration of swivel tool changers into robotic systems will become even more critical. Future applications may include sectors such as healthcare and precision manufacturing, where robots will need to handle increasingly complex tasks with higher levels of dexterity.

The ongoing refinement of swivel tool changer technology will make it possible for robots to perform a broader array of functions without sacrificing efficiency or accuracy, ensuring that businesses can remain competitive in an ever-changing industrial landscape.

Conclusion

Incorporating swivel tool changers into robotic operations is an essential step towards improving efficiency and adaptability. These changers eliminate the need for manual tool changes, significantly reducing downtime and enhancing productivity.

By allowing robots to switch between tasks seamlessly, swivel tool changers help businesses maximise the versatility of their robotic systems, leading to increased output and reduced costs.

At Robotic Products, we are proud to provide high-quality swivel tool changers that meet the demands of modern industry.

As industries continue to push the boundaries of automation, the importance of reliable and efficient tool changers will only grow. At Robotic Products, we are committed to staying at the forefront of this technological revolution.

Our range of swivel tool changers is designed to offer the highest levels of performance, helping businesses across various sectors achieve their production goals. With swivel tool changers, the future of industrial automation looks more efficient than ever.